Dutch ceramics producers ceratec have demonstrated a sintered form of the extremely hard wearing ceramic silicon carbide which could now see use in applications from precision insulators to spacecraft.

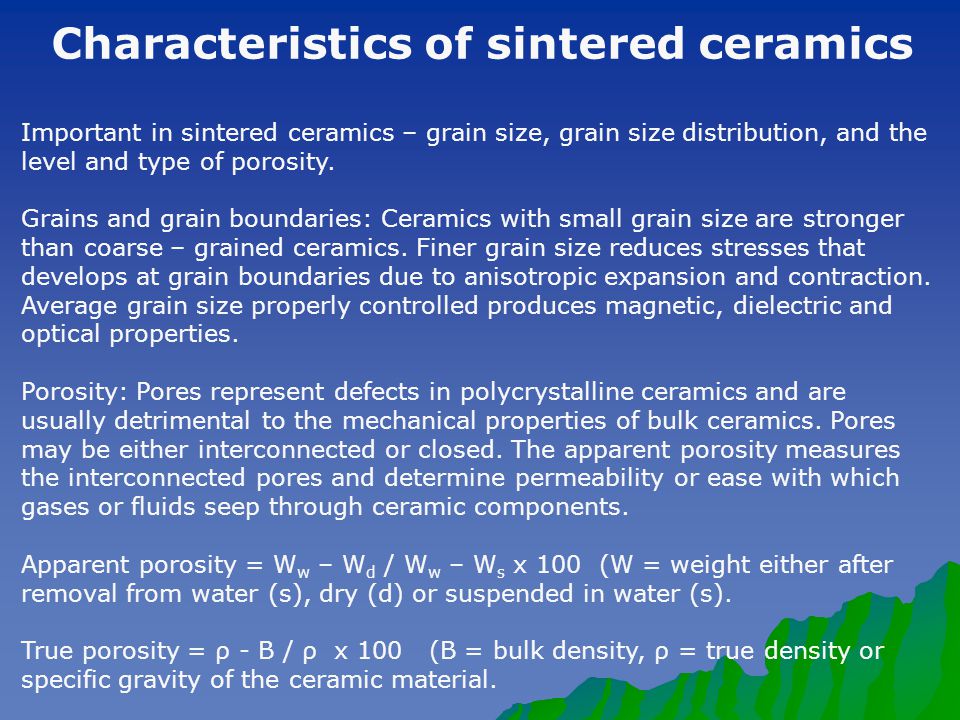

Characteristics of sintered ceramics.

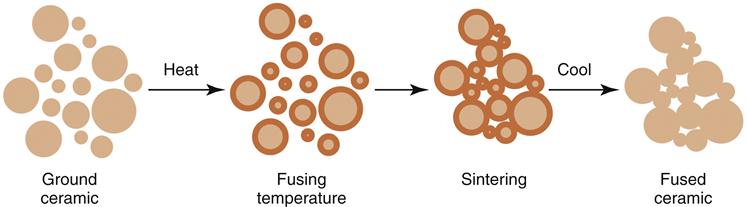

Sintering firing of pure oxide ceramics require relatively long time and high temperature because the diffusion proceeds in solid state.

School of material science engineering shandong university of.

A new production process for high quality durable ceramics is leading to ultra strength materials.

15 the following physical properties are know for a.

The microstructure and grain size of the ceramics may vary depending on the material and method used.

A study was made of the pressing and sinterability of calcium oxide of enhanced purity as a function of the choice of the starting material.

Titanium carbide with special properties has been used for the fabrication of the engineered ceramic components because of its excellent wear resistance high melting temperature 3250 c high hardness 25 gpa relatively low density and high resistance to thermal deformation.

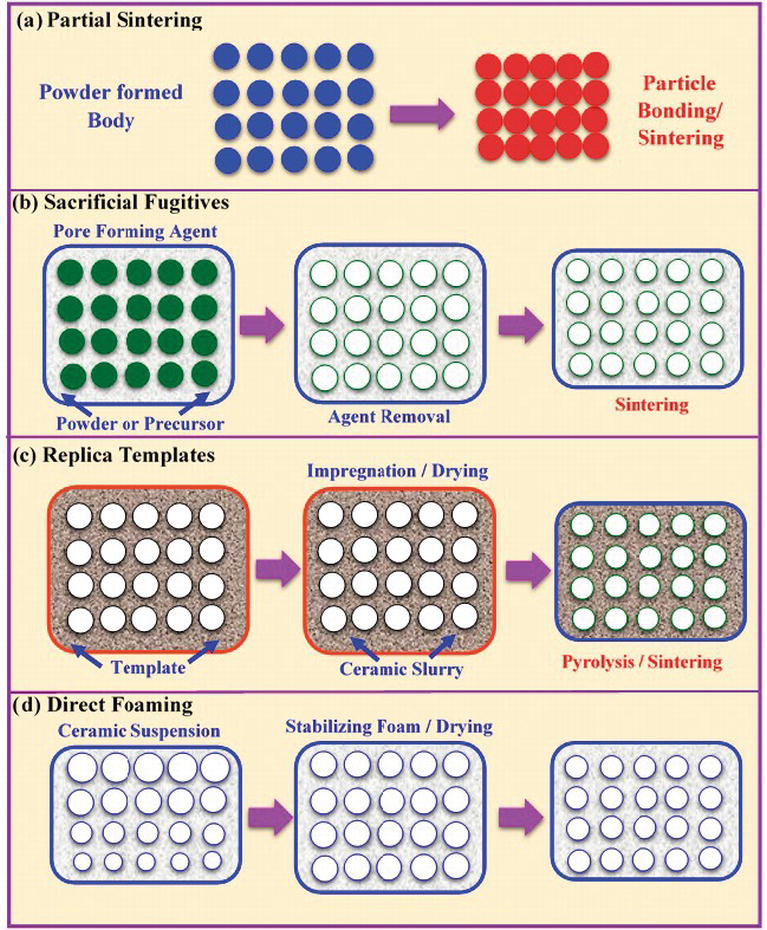

Porous beta si3n4 ceramics with controlled porosity have been prepared using two different routes.

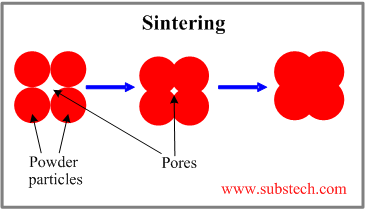

Usually this is done by a sintering process which is a consolidation and densification step of the granular compact through the action of heat.

Three different heating schedules can be performed with pressureless sintering.

15 a sintered zirconium oxide zro2 ceramic has a.

Constant rate of heating crh rate controlled sintering rcs and two step sintering tss.

Sintering is enhanced if a liquid phase takes part in the process liquid phase sintering.

Get ceramic pieces appropriate for the selected application.

Alumina al 2 o 3 zirconia zro 2.

Our wide range of sintered technical ceramics will allow you to make a selection of the most suitable material for your application.

15 the quality control team in a ceramics processing.

The important characteristics of sintered ceramics should be determined.